For many of us, bowhunting opportunities have wrapped up by the end of January and the winter months are a perfect time to do some postseason maintenance on our equipment. The investment that many of us put into our archery arsenal can be significant. Keeping your equipment tuned and well-maintained is critical to its longevity and accuracy, so some basic offseason care and maintenance is important..

Your string and cables are the driving force of your bow and likely see the most use and abuse. Also, because of the nature of string material they break down faster than any other part or your bow. Regular string care is essential, but once bow season has ended, you should do a very close inspection of your strings and cables.

To begin, look closely for fuzzy or fraying stings, broken or cut strands and inspect serving for any separation, especially near stressed locations where cams roll over. Make sure to check the strands that go around your peep sight and look for any cut strands or wear that may indicate any issues with your peep sight. At this time, it’s also important to evaluate the overall condition of your strings and cables and recall the last time they were replaced. Opinions vary some, as do the quality of string material, but I would suggest that strings and cables be replaced entirely every year if you shoot regularly every week, or at a minimum every 18 months to 2 years if you rarely shoot. If it's time for new strings there are many good options that I will briefly cover, but regardless of who makes them, make sure to get a set constructed from quality materials. My favorite are made from BCY 452X, which seems to be an all around workhorse, providing relatively good speed, no creeping or stretching and are stable and durable. If you a looking for more speed and less concerned about the possibility of some stretch or movement then you may consider BCY 8190. The individual strands are smaller, which may help you pick up a few feet per second (fps). BCY Trophy is another good option. These strings are constructed with a combination of GORE and other fibers. Trophy strings are typically more quiet, wear well and are very stable, but may give up some fps to other options. Serving material is also important to consider. I recommend either BCY Halo or Angel Majesty. Both are high quality and will virtually eliminate any issues you may have had with serving separation in the past. All of my strings are locally made by what I consider a master string maker, and I bet with a little research most of you can find a local string maker that builds great stuff, too. I like to buy locally because I believe I get a better product that can be tweaked and built specifically based on what I am looking for in performance. Other options that I trust that can be purchased online or through a pro shop are Winner's Choice, Vaportrail or 60X Custom Strings.

If my strings do not need to be replaced, then I like to give them the royal treatment. Over a season your strings and cables can build up excess wax and dirt.

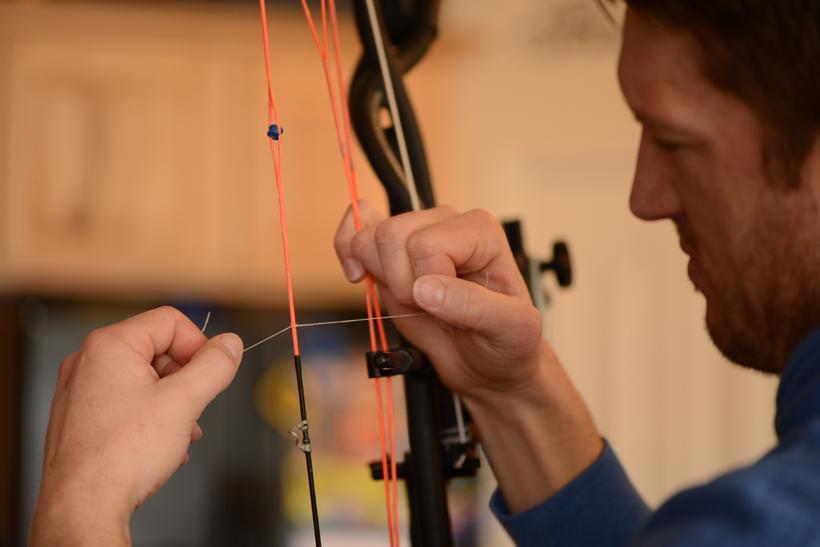

To clean, start with a piece of thin dental floss wrapped one time around your string, while pulling tight, work the floss from the top to the bottom of your stings. The floss acts essentially as a scraper, removing built up wax as you work down the string. You can repeat this multiple times if needed.

Afterward, I prefer to clean them further by using Scorpion Anti-Venom string cleaner. This comes in a small bottle with an applicator tip. You simply apply it down the strings and cables and wait a few minutes before using a clean dry cloth to rub off the dirt, wax and grime that the cleaner pulls out — this is a quick process and is easy to use. Once your strings and cables are clean, they are ready to be waxed once again. There are a lot of good products for waxing bowstrings produced by companies like Bohning, BCY and Scorpion Venom.

My personal favorite is Scorpion Venom Polymeric Wax. If the wax comes in a stick, start by lightly applying a small amount of wax up and down the strings until it is covered. No need to bury the string in the tube of wax, because a little goes a long way.

If it comes in a small tin or can, like the Scorpion Venom, use a small piece of leather or chamois to apply the wax to the string and cable. After you have applied the wax, use your fingers or leather to vigorously work the wax into the string. You are doing it right if the friction heats up the wax and string, and you can see the sheen as the wax works into the stands. Make sure to cover the strings and cables thoroughly. I do not wax the serving portions of my strings, though because I never notice much wear, and I do not want to build up wax in the string and cable tracks of my cams.

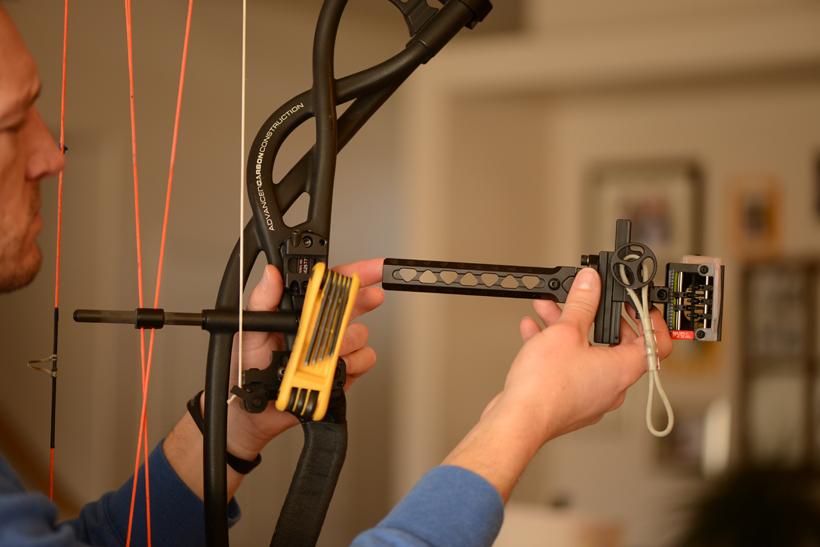

The next step is to take all the parts and pieces off of the bow, but before you do, write down all of the measurements of the bow to remove any guessing when you put it back together.

Note the sight marks, the rest tick marks, the location and angles of stabilizers, and anything else that will be needed to put it back together as it was before.

Next, using an allen wrench, break things down to the bare bow. Take the rest off, the sight, all stabilizers and quiver.

Putting those pieces aside, take a damp cloth and working from one end of the bow to the other, wipe down the bow. Wipe off any dirt, dust, blood, or whatever kind of grime you may have gotten into.

Use moistened Q-tips to wipe out any hard-to-reach nooks within the riser and cams of your bow. Once you have it thoroughly cleaned, allow it to air dry or use a small, clean dry cloth to follow up.

While cleaning, carefully run a dry cottonball along the edges of your limbs watching for any snags that may indicate a splinter in your limbs. Any splinter should likely be looked at more closely and taken to your local pro shop to fix.

Next, continue onto your rest, sight and stabilizer in the same manner. Wipe parts down with a damp cloth, using a damp Q-tip to get into the hard-to-reach spaces that build up dust and dirt, like the spaces between your pins.

Also check your fluorescent pin fiber for breaks. A small break in a pin fiber can likely be fixed with a spot of fletching glue without too much loss in brightness. This shouldn’t be difficult, since most sights are easy to remove and replace the fiber.

While you have your strings off, either check yourself or have your bow technician check your axles for unusual wear and see that they are straight. Most current-model bows have sealed ball bearings within the cam. Check those while you have the strings off to see that they spin smoothly. They should move smoothly and track straight with no wobble. No lubrication is needed in or on the bearings, but annually you should add a very faint sheen of a teflon or silicone based lubricant to the axle.

When you first purchased your bow you likely noticed the limb bolt running through the limb pocket and into the riser was greased. If you are breaking down your bow, back the limb bolts out and clean the pockets and re-grease them with a white lithium grease. After you have your bow cleaned, the limbs and cams assembled and the new strings on, check your cam timing to see that it is correct. If not, now is the time for you or your pro shop to make the necessary adjustments.

While re-attaching your components, I recommend lubricating the threads of all your hardware with a anti-seize lubricant. In a pinch, you can even use bowstring wax. This is especially important for your stabilizer bolts as vibration running through your bow shot after shot can cause your stabilizers to cease up and you may not get them off without some serious effort.

After you put your bow back together you should take some time to go through all of your arrows. Flex them individually, listening for cracks and looking for damage. Any damaged arrow should be removed from your quiver. Shooting a damaged arrow could result in a horrible outcome. Also, be sure to check your nocks. Look for cracks or bent nocks and replace them as needed. I also like to spin every arrow again, either on an arrow spinning device or by blowing on the vanes and turning them in my hand. Look for any wobble. An arrow that is less than straight can still be shot, but it gets a lower number in the quiver and never makes its way into the field with a broadhead on it. Other items you should check and clean are your release aid and broadheads. Broadheads should have all rust removed. If possible, broadheads should be resharpened and put back into the packaging. Spot Hogg has a neat new broadhead sharpener that looks very impressive. Your release should be evaluated for any sounds, delay, dirt or grime. If there is any issue and you are a bit of a tinkerer you can disassemble, clean and lubricate it. If not, replace it. A well maintained and tuned bow will serve you well for many years to come. There is truly no better thrill than getting close and making it happen with a bow and arrow.